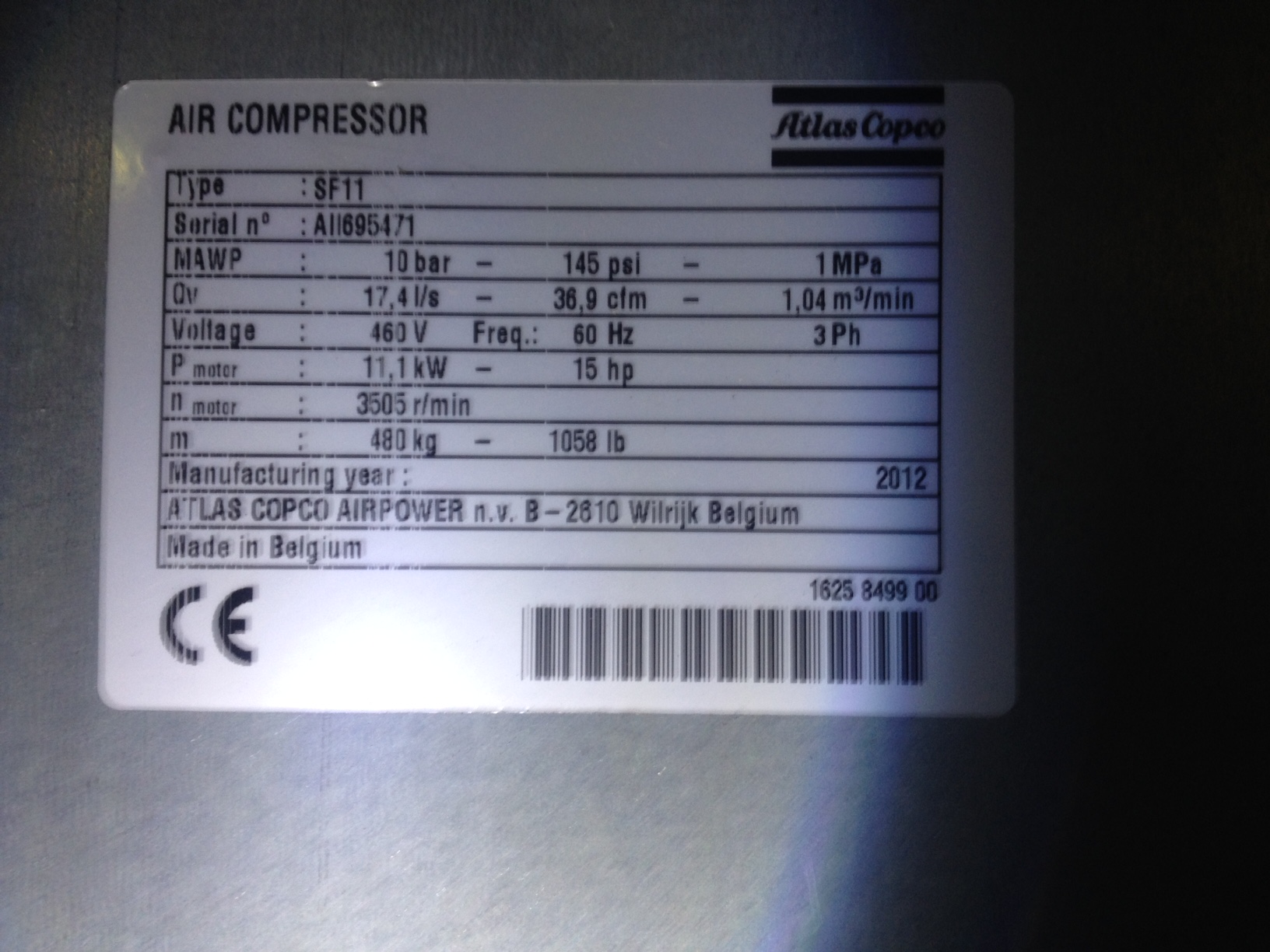

manual - Atlas Copco SF manual

parts - Atlas Copco SF parts/kits

Scroll_greasing - Atlas-Copco instructions for scroll service

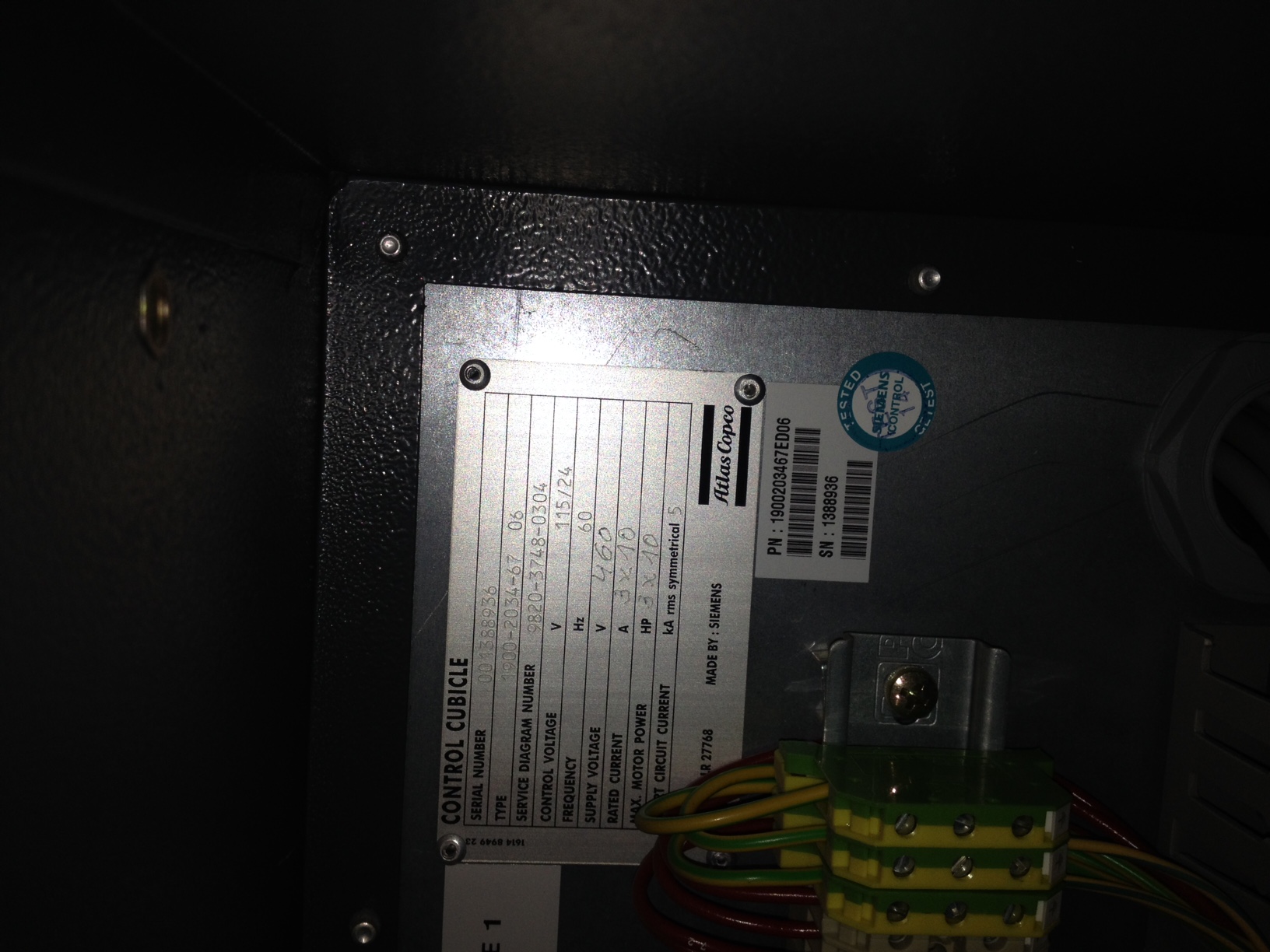

Contactor Siemens (3RT1026-1AK60): order - img1 - img2 - img3 - img4 - img5 - data_sheet

repairs1 - Repair manual from Atlas-Copco

repairs2 - Service tutorial of scroll tips etc

repairs3 - Service tutorial of scroll tips etc (another vendor further)

overview - Overview of scroll compressor

invoice - Invoice with part #'s from a repair

invoice2 - Air Engineering Invoice with part #'s

invoice_pump - Invoice for scroll replacement from Anest Iwata

Order service - Atlas Copco homepage

Order replacement parts - Air Engineering

Order replacement parts2 - Capco homepage

| Item | Part # | Cost (each) $ |

|---|---|---|

| Air Filter | 1622 0658 00 | 24 |

| Check Valve | 2236 0438 80 | 130 |

| Outlet Pipe | 2901 1397 00 | 54 |

| Tipseal Kit | 2901 1584 02 | 1049 |

| V-Belts ( = 1513 0289 37) | 2903 1021 37 | 63 |

| - | - | - |

| Grease Cartridge | 2892 6100 20 | 270 |

| Grease Pump | 2903 0139 00 | 166 |

| Part # | location |

|---|---|

| 1630 1439 00 | Fixed scroll, High pressure (inner/shorter) |

| 1630 1439 10 | Fixed scroll, Low pressure (outer/longer) |

| 1630 1439 20 | Orbiting scroll, High pressure (inner/shorter) |

| 1630 1439 30 | Orbiting scroll, Low pressure (outer/longer) |

| 1630 1439 40 | Dust seal |

| 1630 1439 50 | Dust seal (tubing goes in first to fixed scroll) |

General repair notes:

- 13mm wrench for mount bolts, 17mm for scroll bolts, 9/32" nut drive, allen wrench 5.5mm belt tension?

- turnoff compressor with keypad

- shutoff drainvalve

- push 'test' button on automatic drainvalve and let pressure to scrolls drop

- to turn off power throw white breaker that is labelled "compressor"

- -

- remove belts by loosening 4 motor bolts then adjust tension bolts to motor with allen wrench. once belts are off remove four bolts on scroll as well. can grease OS once scroll is free from mounts by moving slightly out while in cabinet.

- there is a thermocouple that needs a nut driver ( mm)

- -

- use airgun to clean compressors cooling fins and fan

- to replace tipseals remove 6 large bolts ( mm)

- one bolt is under cooling fan cover (short one)

- use wooden tongue depresser to push in seals as metal is too harsh

- use 6 pumps of grease for 3 crankpins that are now accessible with scroll open

- use 6 pumps of grease for OS as well

- -

- when replacing checkvalves be sure to save the stoppers for new ones!

- note to grease we need the needle point for both orbiting scroll and crankpins

Service performed

April 2018 - replaced tipseals, greased crankpins and oribiting scroll, replaced check-valves and straight pipes, replaced air filters, cleaned scroll, replaced burnt out contactor k23. April 2019 - replaced belts, air filters and greased orbiting scroll. Scroll compressor number 3 froze up and needs to be replaced. Replaced 3rd (top) scroll compressor. November 2020 - replaced belt on top scroll (3) that burnt into cover. Replaced scroll cover the belts had damaged. Replaced air filters and greased orbiting scrolls. Reset counter for service. Ordered 6 sets of V-belts and put them in RRC. April 2022 - replaced air filters and greased orbiting scrolls. Reset counter for service (was at 5k, plan ab). Ordered 9 air filters. Dec 2022 - replaced belts on all 3. greased orbiting scroll and crankpins on all 3. replaced K21 as scroll 3 was tripping on shutoff. Feb 2024 - greased orbiting scroll on all 3. replaced 3 air filters. ordered 1 grease and 2 v-belt sets.